Why Residential MEP Design Still Happens on the Back of a Napkin

Published

November 13, 2025

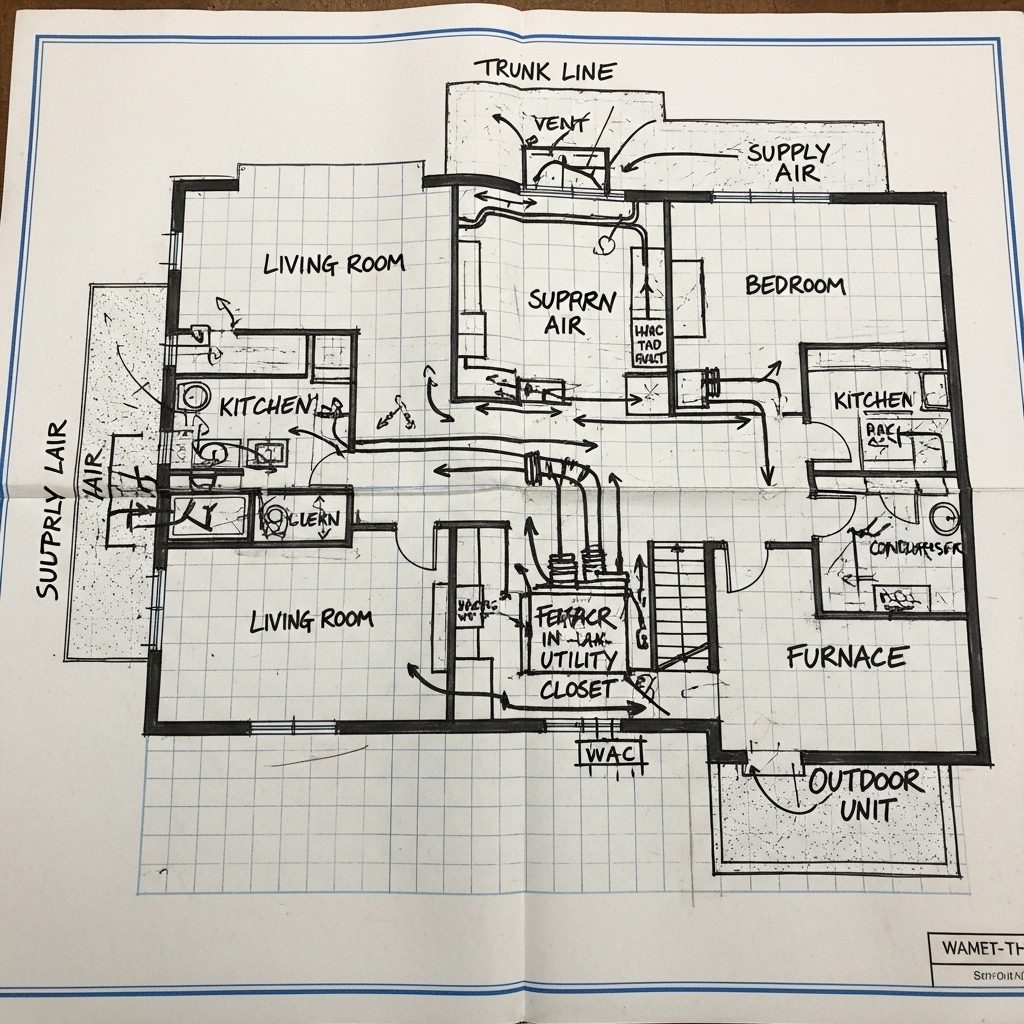

Residential construction runs on intuition, experience, and…Sharpie markers. In 2025, most MEP systems in new homes are still designed the same way they were in 1985. The systems that make a home habitable: the mechanical, electrical and plumbing (MEP) systems, are too often treated as after thoughts. These systems are essential to how a home functions. They provide you water from your sink, air through your vents, and light in your rooms. However, unlike the aesthetics of a house, in 80% of cases these systems are never properly designed on a plan set. If you walk onto most residential job sites, you'll find HVAC installers, electricians, and plumbers figuring things out as they go - often sketching (yes, you read that right) on drywall or a floorplan. Why?? Primarily because this is the way it's been for decades.

The consequences of this incoordination and lack of planning are substantial: expensive rework, wasted time, structural compromises, major delays and unhappy owners are the tip of the iceberg.

Why does this keep happening?

1. Architects lead, systems follow

Floor plans are completed and framing often starts before any detailed MEP design begins. By the time trades arrive, they're left to interpret intent rather than follow a coordinated plan.

2. Coordination is an afterthought

Because systems are designed in isolation and installed at different times, clashes are inevitable.

• Plumbing fights for ceiling space with HVAC.

• Unexpected bulkheads and dropped ceilings appear late to cover mistakes.

• Schedules slip as crews wait for others to finish before starting.

Everyone adjusts downstream and the result is chaotic. The lack of coordination is the most detrimental part of this whole process.

3. No digital feedback loop

Unlike commercial construction, residential projects rarely use Building Information Models (BIM) or clash detection tools. Each house becomes its own improvised coordination effort, with no record of what was actually built. When something goes wrong, there's no model to reference - just countless emails with pdfs, photos, or guesswork.

This fragmented process (#1-3) produces the same results every time: inconsistent installations, margin-killing rework, schedule delays, and strained relationships between trades and builders.

The bottom line is, it's quite unbelievable that these systems are still figured out using brute force and photos of scribbles sent back and forth. For systems that are complex and so integral to safety, comfort and the functionality of a home, it seems almost counterintuitive to go in without a plan. This is exactly the gap CORDAX was built to solve. Not by replacing consultants, but by giving builders and installers a way to arrive on-site prepared. The platform takes an architectural floor plan and generates coordinated HVAC, plumbing, and electrical layouts in a navigable 3D environment - creating a shared, build-ready reference before framing begins.

The difference between guessing and planning is the difference between costly improvisation and predictable execution. CORDAX doesn't automate construction - it eliminates preventable chaos so trades can do their best work.

The consequences of this incoordination and lack of planning are substantial: expensive rework, wasted time, structural compromises, major delays and unhappy owners are the tip of the iceberg.

Why does this keep happening?

1. Architects lead, systems follow

Floor plans are completed and framing often starts before any detailed MEP design begins. By the time trades arrive, they're left to interpret intent rather than follow a coordinated plan.

2. Coordination is an afterthought

Because systems are designed in isolation and installed at different times, clashes are inevitable.

• Plumbing fights for ceiling space with HVAC.

• Unexpected bulkheads and dropped ceilings appear late to cover mistakes.

• Schedules slip as crews wait for others to finish before starting.

Everyone adjusts downstream and the result is chaotic. The lack of coordination is the most detrimental part of this whole process.

3. No digital feedback loop

Unlike commercial construction, residential projects rarely use Building Information Models (BIM) or clash detection tools. Each house becomes its own improvised coordination effort, with no record of what was actually built. When something goes wrong, there's no model to reference - just countless emails with pdfs, photos, or guesswork.

This fragmented process (#1-3) produces the same results every time: inconsistent installations, margin-killing rework, schedule delays, and strained relationships between trades and builders.

The bottom line is, it's quite unbelievable that these systems are still figured out using brute force and photos of scribbles sent back and forth. For systems that are complex and so integral to safety, comfort and the functionality of a home, it seems almost counterintuitive to go in without a plan. This is exactly the gap CORDAX was built to solve. Not by replacing consultants, but by giving builders and installers a way to arrive on-site prepared. The platform takes an architectural floor plan and generates coordinated HVAC, plumbing, and electrical layouts in a navigable 3D environment - creating a shared, build-ready reference before framing begins.

The difference between guessing and planning is the difference between costly improvisation and predictable execution. CORDAX doesn't automate construction - it eliminates preventable chaos so trades can do their best work.

Thanks for reading!

Share this article if you found it helpful and inspiring.

Published by CORDAX Team

© 2025 CORDAX. All rights reserved.